Safe storage of wheat and barley grain

By Jeremy Boychyn (M.Sc)(P.Ag), Agronomy Research Extension Manager | Alberta Grains

With a highly variable crop coming off in the central and northern parts of Alberta, storage considerations will need to be front of mind. After a dry early and mid-season, late tillers have emerged due to the later summer rains. These late tillers increase moisture in the harvested grain and can create storage risks. See here for more information of variable crop management

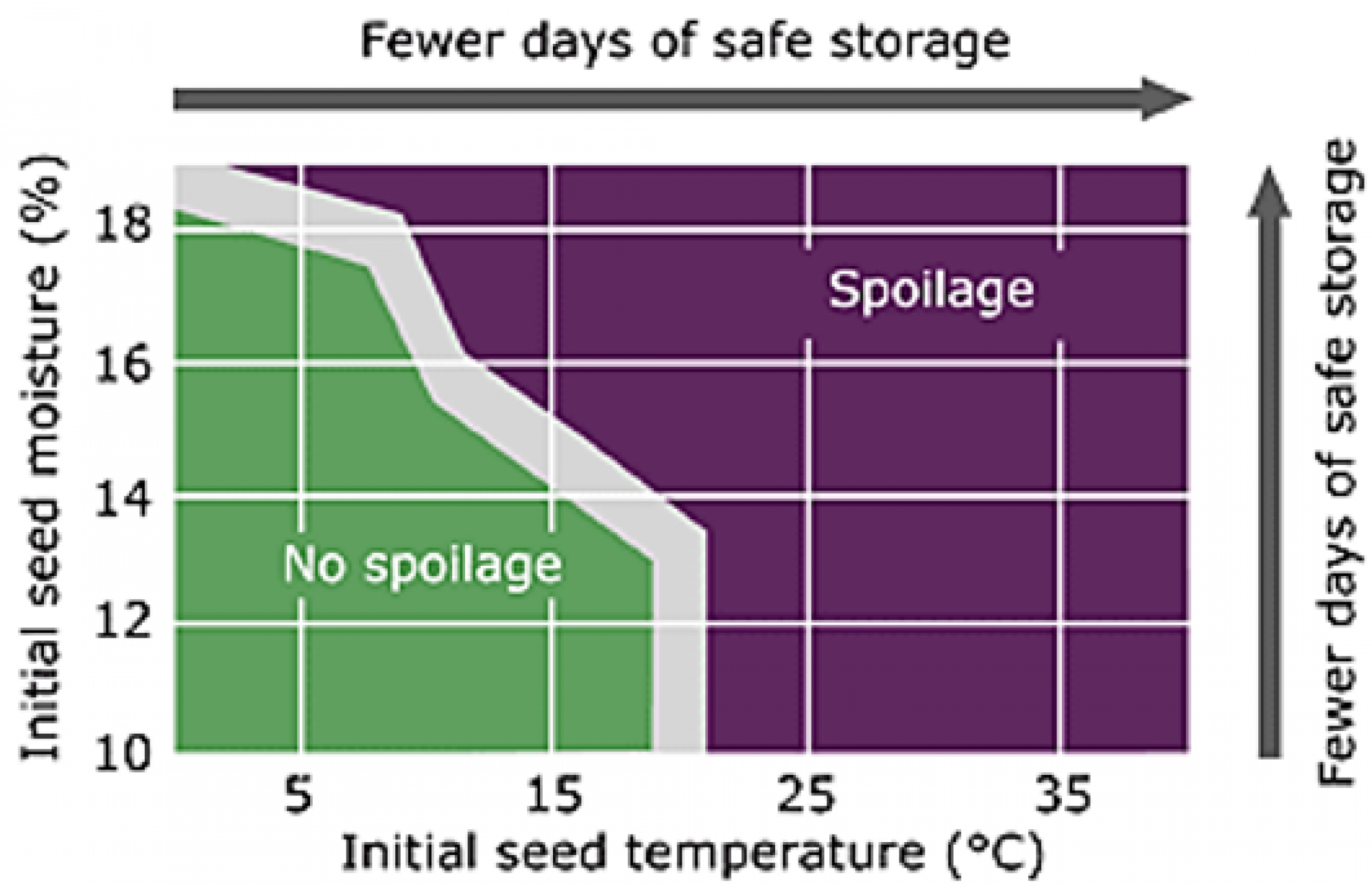

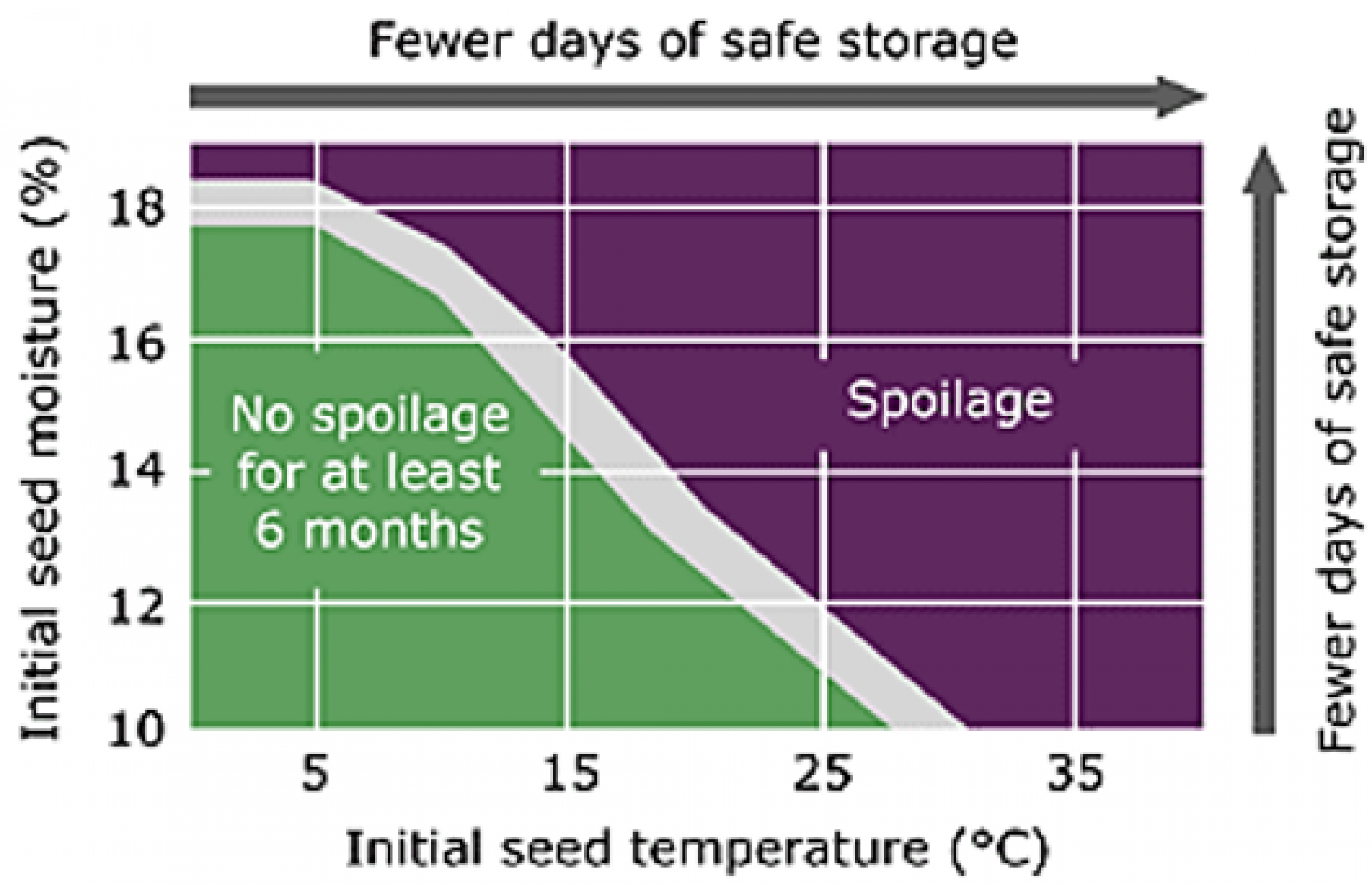

Safe storage of wheat and barley grain comes down to two factors: grain temperature and moisture. If one or both factors are not properly managed, the risk of spoiled grain increases significantly. The Canadian Grain Commission (CGC) developed stage storage charts for both wheat and barley (Figures 1 and 2). If the initial temperature and moisture of the wheat or barley grain is within the ‘spoilage’ range (purple areas) of these charts, the risk of spoilage is higher (i.e., 16% seed moisture at 25°C). According to the CGC, if the temperature and moisture content falls within the ‘no spoilage’ range (green areas), the crop can be safely stored for up to five months, or six months in the case of wheat (i.e., 15% seed moisture content at 5°C). However, this does not mean the grain can be left unchecked over those five to six months. Continued monitoring of the grain and grain bins is essential to ensure conditions do not change. Depending on environmental conditions during storage, moisture or temperature conditions of the grain can change leading to spoilage. Luckily, many technology-based systems are available to help monitor bins without having to physically sample the bins.

For more information on what the CGC considers tough and damp moisture ranges, see here.

Figure 1: Safe storage chart for barley (Source: Canadian Grain Commission https://www.grainscanada.gc.ca/en/grain-quality/manage/manage-storage-prevent-infestations/prevent-spoilage.html)

Figure 2: Safe storage chart for wheat (Source: Canadian Grain Commission https://www.grainscanada.gc.ca/en/grain-quality/manage/manage-storage-prevent-infestations/prevent-spoilage.html)

One of the best ways to mitigate spoilage is to harvest the grain when the moisture content is within the safe storage range. If the grain is harvested at the ideal moisture range, grain can immediately go into storage or receive aeration if the grain temperature needs adjustment (i.e., if grain is harvested at 16% seed moisture at 25°C the grain will need to be cooled to 10°C safe storage). However, this scenario is rarely the case. Between variable tiller maturity and a short harvest season, harvesting the grain prior to ideal moisture content is commonly needed to avoid yield and quality loss. This means post-harvest grain management must be implemented to condition the grain and reduce spoilage risk.

Swathing can be used to bring grain closer to the desired moisture range prior to harvest and storage. With variable crops, swathing can reduce variability by allowing the later tillers to dry down and reach a lower moisture level which reduces the risk of stored grain spoilage. However, this does not completely remove risk as wet weather can reduce the quality of grain in a swath.

However, swathing is not always an option. Even if it is an option, it will not always bring grain completely to storable moisture conditions. This is when tools such as natural air drying (NAD), NAD with supplementary heat, and heated air drying may need to be implemented. Use of these options will depend on on-farm equipment availability, drying availability and discounts at local elevators. If on-farm options are not available, some local elevators charge a fee for grain drying service. In some fortunate cases, neighbours with grain dryers may also have grain drying capacity. NAD requires the use of a bin with a airflow system to remove moisture through forced airflow. However, NAD requires appropriate ambient air temperatures and favorable relative humidity to remove moisture from grain. The addition of supplemental heat to an NAD system can increase the utility of the NAD. Prairie Agricultural Machinery Institute (PAMI) has developed a useful guide for supplemental heat for NAD systems that can be found here. Finally, a heated air grain drying system can also be utilized to dry grain to an appropriate moisture content for longer term storage. However, these systems can be expensive to install and operate. Examples of grain dryer cost and operational information can be found here.

The bottom line is that crop and weather conditions can cause significant challenges when it comes to safe grain storage. Storing grain at moistures and temperatures outside of the safe storage range (Figure 1 and 2) can lead to significant spoilage. Producers must take steps to protect their grain through appropriate harvest management, grain conditioning, grain drying and grain storage options.